Conran Construction Group has realized digital and online management of the project by using POS project management system.

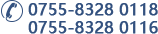

POS project management system provides the most professional, intelligent, easy-to-use public decoration industry customer management CRM, schedule planning and management (PM) tools and services for the field of architectural decoration design engineering! Assist the project to quickly and effectively formulate reasonable project demand follow-up plan and project schedule plan from the source, deduce the optimal design scheme and construction scheme, and avoid conflicts in design and construction in advance; Assist the comprehensive optimization of projects in the construction process, timely and accurate warning of risks, and provide the basis for dispute resolution; Truly distinguish the responsibilities of each profession, and finally realize the quality of "collaborative construction"; To effectively shorten the construction period, save costs, enhance the competitiveness of enterprises, to achieve the goal of "high quality" project results delivery!